Overview: “TMWalker4 in manufaturing” at Berco

Phase 1: Central part

The central part is finished. Comparable to the generic Transmodel data model for Public Transport, we have now created a generic manufacturing database. After studying the ERP system of Berco and SAP, we created a database for a production process. We defined an interface with the ERP system and the transmission of data is now functional. The work orders go from the order administration into the manufacturing database and afterwards we send notifications back into the order administration. Of course, there are more details in the TMWalker4 database than that is needed for the ERP system. This connection would not have been possible without the help of Berco’s IT department and some users we could interview.

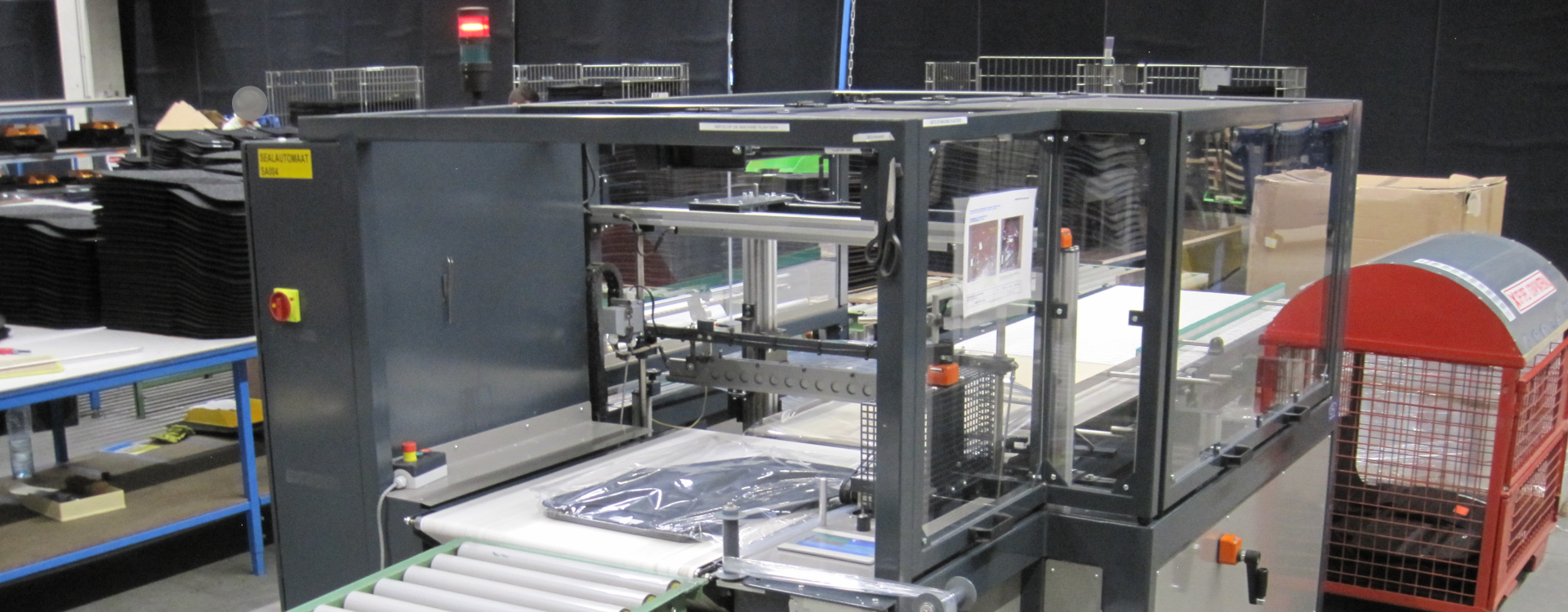

Phase 2: Proof of concept: the sealing machine

Digitron and LabelSolutions have helped in creating a test setup. The seal (as a set of usually 4 car carpets, packaged in a transparent seal) are automatically given a unique barcode (which we call Bercode) and with a vision-label scanner, both the client label and the Bercode are scanned. Scanned, unique Bercodes of the seals are saved in the database for track-and-trace possibilities. Using a vision-label scanner opens up the possibility the measure the quality of the client labels and report about it.

The sealing machine is a work post. The operator needs to scan a work order and will see a wizard-like dialogue in TMWalker4. The operator is guided through the steps. After registering the barcodes and connection the seal, case and work order, there are also quality checks implemented in the dialogue. For example, a picture is also shown for a visual check.

At the moment we are busy working on testing and improving the new way of working and the dialogue for the sealing machine. If all seems to be good, we’ll transport it to the production hall. First, only for the carpets of one client, secondly for all clients.

We’ll keep you updated!

0 Comments